High thermal conductivity and simpler processing

Is the module solution costly? Is the single tube design complicated? Is the heat dissipation problem tricky? Insulation cloth is easy to age? Ceramic insulation sheets are easy to break?

Everyone who is a motor-driven driver must have experienced the above troubles. With the gradual intensification of market competition, the single-tube solution in the motor driver market is becoming more and more popular. The circuit using IGBT single-tube has the advantages of low cost and more flexible layout than modules such as IPM and PIM, and can significantly improve customer products. Is the price. In the case of a generic 400W servo drive, the single-tube solution and the IPM solution have a 10%-20% difference in the overall BOM.

The single-tube solution has allowed many customers to taste the sweetness of cost down, but it also brings some troubles. For various reasons, the single-tube solution defect rate is always slightly higher than the module, which will undoubtedly bring more after-sales costs. This is why many engineers still respect the single-tube program. Although there are many factors that cause high defect rate in single-tube solutions, they are summarized in two aspects: system design and device performance. The system design has become more and more mature. After years of research, the circuit matching and structural layout have been greatly improved, and the optimization space is limited in the short term, so the choice of devices is particularly important.

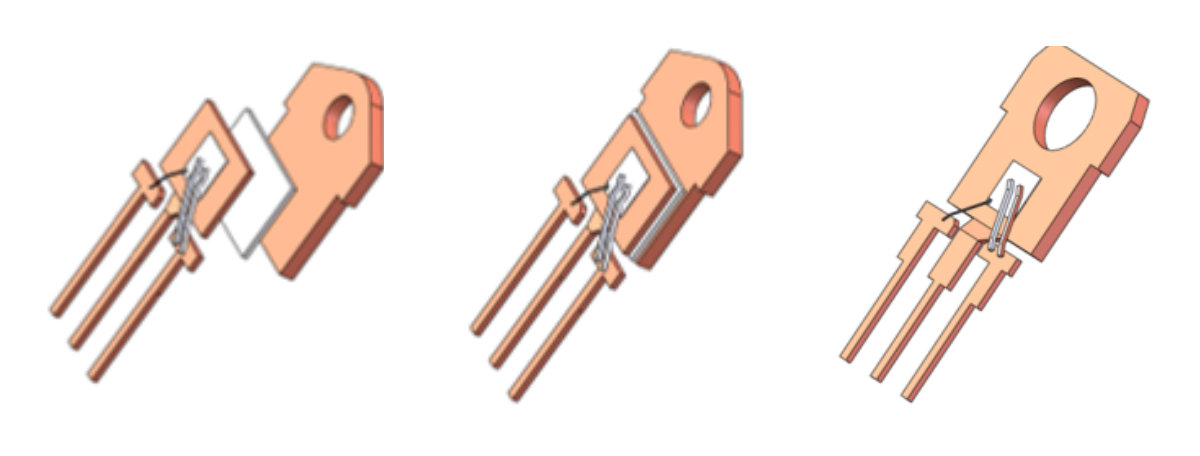

Core energy ceramic internal insulation series single tube is to help customers solve the short board of the device, optimize the design from the two aspects of insulation capacity and thermal conductivity, to provide a reliable guarantee for the high stability of the single tube solution.

Core-energy ceramic internal insulation IGBT single tube has the following advantages:

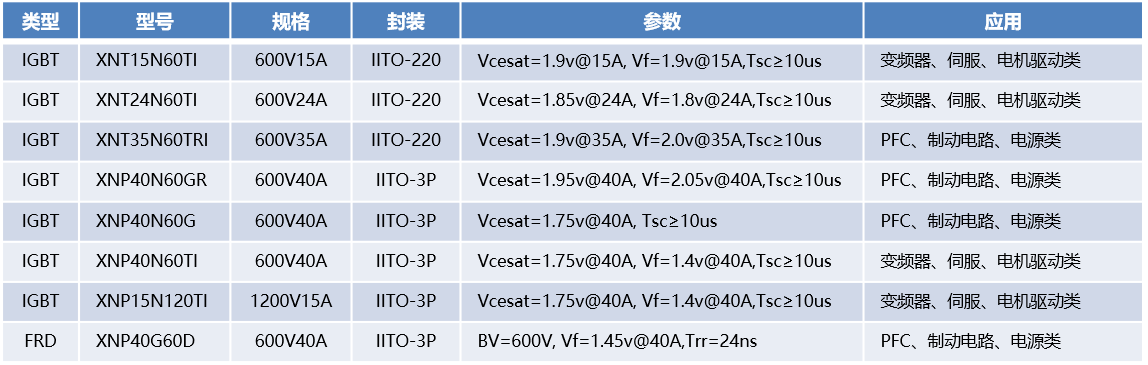

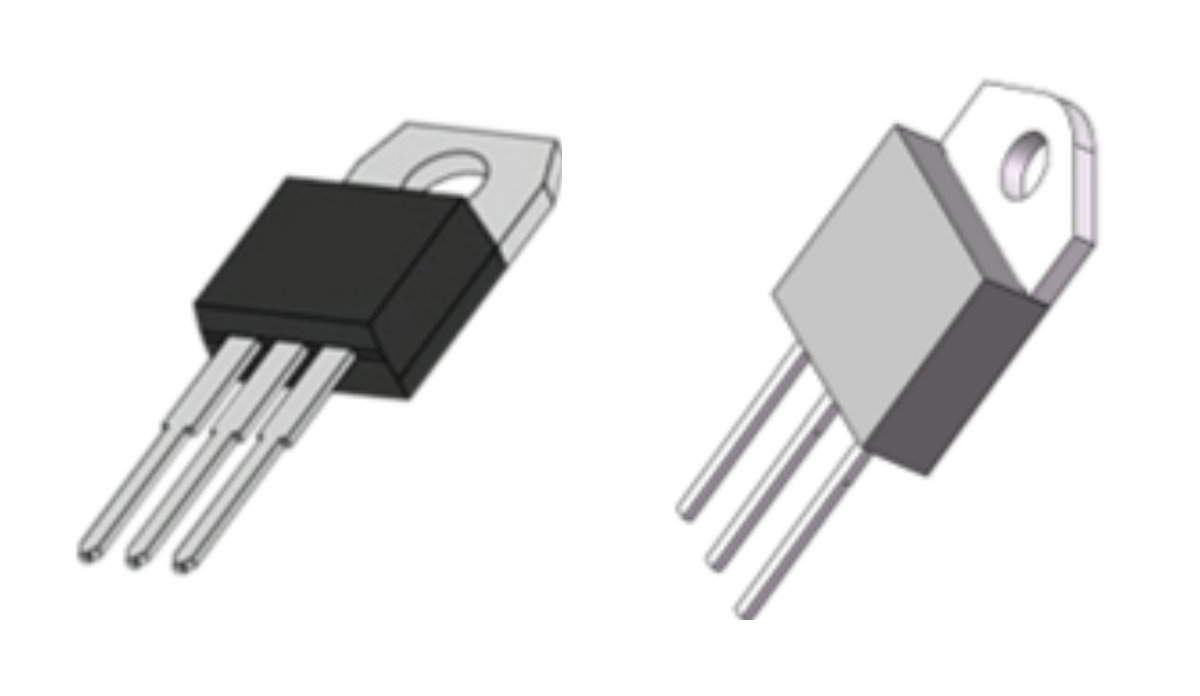

At present, the core energy insulated IGBT has two package forms, IITO-220 is compatible with the traditional TO-220, TO-220F package form; IITO-3P is compatible with the traditional TO-3P, TO-247 package. The following is a list of the core products of this series, for more information, please contact us at the core company!